Development of Novel Tool Using Taguchi for the Near Future

Ikuo Tanabe

Nagaoka University of Technology, Kamitomioka, Nagaoka, Niigata, Japan

- *Corresponding Author:

- Ikuo Tanabe

Nagaoka University of Technology

Kamitomioka, Nagaoka, Niigata, Japan

Tel: 0081258479727

E-mail: tanabe@mech.nagaokaut.ac.jp

Abstract

As of late Taguchi techniques are utilized to choose ideal preparing conditions with thin scattering for powerful plan. Then again, imaginative improvement with short-term, minimal effort, work sparing and vitality sparing is additionally required on the planet. In this exploration, the product for creative instrument utilizing Taguchi techniques is created and assessed. There are two sections in the inventive device; the Part 1 is the management for creation and the Part 2 is the examination for examination with respect to the impact of the control components. In the Part 1, the Taguchi techniques were initially computed the normal and the standard deviation with respect to all mixes utilizing all parameters. The administration of generation was at last used to choose the ideal blend of all parameters for achievement rate, exactness, fabricating time and aggregate cost. Likewise, the spring back of warm press shaping on magnesium compound plate was explored for assessing this framework in the investigation. It is finished up from the outcome that this framework successfully anticipated ideal process conditions in every need and the anticipated outcomes adjusted to the aftereffects of the spring back test. In the Part 2, this part is firstly expert for selecting essential control variables, and the following trial chooses the ideal blend of the control calculates by more detail trial. The ideal condition for cooling framework at cutting was examined for assessing this development apparatus in the analysis. It is finished up from the outcome that this framework was valuable for improvement with transient and lower cost and this instrument could rapidly and precisely choose the ideal cooling condition.

Keywords

Taguchi-methods, Innovation, Optimum condition, Software

Introduction

As of late advancements with fleeting and lower cost are emphatically required for abbreviate items life cycle. Along these lines Taguchi-strategies [1-4] are utilized for choosing ideal process conditions. However these strategies are insufficient to build up another item with brief time, bring down cost, high calibre and high precision.

In this exploration, the product for imaginative device utilizing Taguchi techniques is created and assessed. There are two sections in the inventive device; the Part 1 is the management for generation and the Part 2 is the examination for examination with respect to the impact of the control components. In the Part 1, the Taguchi techniques were initially figured the normal and the standard deviation in regards to all mixes utilizing all parameters. The administration of generation was at last used to choose the ideal mix of all parameters for achievement rate, exactness, producing time and aggregate cost. What's more, the spring back of warm press shaping on magnesium combination plate was explored for assessing this framework in the analysis. In the Part 2, this part is firstly refined for selecting essential control variables, and the following trial chooses the ideal mix of the control considers by more detail trial. The ideal condition for cooling framework at cutting was examined for assessing this advancement instrument in the examination. What's more, the apparatus base has effectively made by my examines.[5-7],[12-14]

Explanation of Taguchi-Methods

The Taguchi-method is utilized to choose ideal preparing conditions with tight scattering for vigorous outline. Along these lines the Taguchi-techniques is clarified in this segment. [8]

Control elements are equivalent to the outline elements (Table 1). Clamour elements are happened for the mistake of capacity on the item (Table 1). Most architects can comprehend that the last elements of the created item are unequivocally affected for the every lever of every control figure under a few commotion components. All blends utilizing all control variables are packed by an orthogonal table (Table 2).Then the examination or the CAE investigation with impact of commotion components is performed by the orthogonal exhibit. Finally, the normal and the standard deviation in regards to all blends utilizing all control elements are ascertained for the SN proportion and Sensitivity. Those were ascertained by conditions of (1) and (2).

SN ratio (db)=10 log (μ22) (1)

Sensitivity (db)=10 log μ2 (2)

| Control factors | ||||||

| Name | A | B | C | D | ||

| Levels | A1 | B1 | C1 | D1 | ||

| A2 | B2 | C2 | D2 | |||

| A3 | B3 | C3 | D3 | |||

| Noise factors | ||||||

| Name | N | |||||

| Levels | N1 | N2 | N3 | |||

Table 1: Control and noise factors in Taguchi-methods.

| Trial. No. | Control factors | Result with noise factors | SN ratio (db) | Sensitivity (db) | |||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | N1 | N2 | N3 | |||

| 1 | A1 | B1 | C1 | D1 | 2.7 | 2.6 | 2.4 | 24.5 | 8.2 |

| 2 | A1 | B2 | C2 | D2 | 2.3 | 2.2 | 2 | 23 | 6.7 |

| 3 | A1 | B3 | C3 | D3 | 2.1 | 1.9 | 2 | 26 | 6 |

| 4 | A2 | B1 | C2 | D3 | 3.3 | 3.1 | 3 | 26.2 | 9.9 |

| 5 | A2 | B2 | C3 | D1 | 4.6 | 4.4 | 4.5 | 33.1 | 13.1 |

| 6 | A2 | B3 | C1 | D2 | 3.3 | 3.3 | 3 | 25.3 | 10.1 |

| 7 | A3 | B1 | C3 | D2 | 2.1 | 2.3 | 2.4 | 23.4 | 7.1 |

| 8 | A3 | B2 | C1 | D3 | 3.1 | 3.2 | 3.1 | 34.7 | 9.9 |

| 9 | A3 | B3 | C2 | D1 | 4.7 | 5.1 | 4.9 | 27.8 | 13.8 |

Table 2: Orthogonal array, SN ratio and sensitivity in the Taguchi-methods.

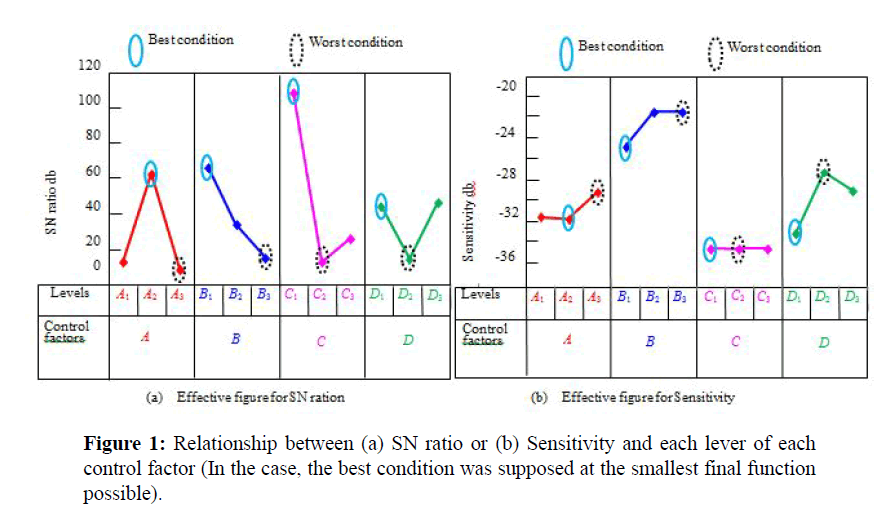

Where μ is normal of the assessment esteem and σ is standard deviation of the assessment esteem in the consequences of CAE. The assessment vale is the spring back in the later CAE re-enactment. At that point a large portion of clients compose the powerful figure (Figure 1) of the control components and fanatically look the mix of the control variables for expansive SN proportion. An item utilizing the mix isn't almost affected by clamour variables. The CAE part was then utilized for shortening the aggregate time of assessment with respect to the plan elements of the development. The CAE part is a sub program for the part of Taguchi methods. This simulation can calculate much behaviour; those are static, dynamic and thermal behaviours, vibration and flow of a fluid, large deformation such as cutting, press forming, crash or explosion. The control factors in the Taguchi methods can directly input to the CAE simulation. With regard to the noise factors in the Taguchi methods, it also can input directly or the properties of dependence on temperature, time or boundary conditions.

At last, the average and the standard deviation regarding all combinations using all parameters are calculated by the SN ratio and Sensitivity with 18 kinds. The addition theorem in the Taguchi methods was used for calculating the results for all combinations. For example, when m is a control factor and n is the level for the factor, the SN ratio SNmn and Sensitivity Smn for the control factor m and the level n are calculated by the addition theorem. Moreover the SN ratio SNa4b2c1d3e2f1g2 and the Sensitivity Sa4b2c1d3e2f1g2 for a4, b2, c1, d3, e2, f1, g2 using control factors (a, b, c, d, e, f, and g) and levels (1, 2, 3, 4, 5 and 6) were calculated by the equations (3) and (4), respectively.

SNa4b2c1d3e2f1g2=SNa4+SNb2+SNc1+SNd3+SNe2+SNf1+SNg2(71) SNave (3)

Sa4b2c1d3e2f1g2= Sa4+Sb2+Sc1+Sd3+Se2+Sf1+Sg2(71) Save (4)

Where SNave and Save are each average of the all SN ratio and the all Sensitivity, respectively.

The Management for Production

Explanation for management regarding production

This strategy has a few components; it can diminish the trial numbers in the CAE recreation, it can demonstrate the impact of the blunder elements and it can rapidly ascertain the greater part of the outcomes with respect to all mixes of all parameters. [9,10]

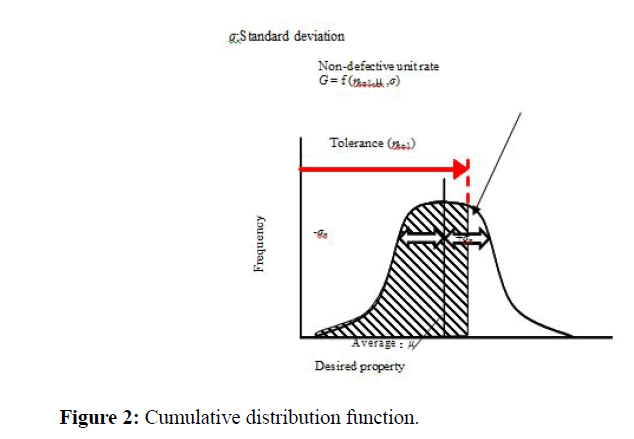

The administration piece of efficiency was at long last utilized for selecting the ideal esteem with respect to all parameters. This part got both the normal and the standard deviation for all blends of all parameters on the Taguchi strategies part, the all frequencies of event are then figured by the total appropriation work with the normal and the standard deviation. An aggregate conveyance capacity is appeared in Figure 2. In the event that the resilience ηtol is chosen, non-inadequate unit rate G is figured by the aggregate dissemination work, [11] for example, condition (5).

Gηtol (5)

NNordG (6)

Tm(from 1 to final machine number) TV (7)

TallN Tm (8)

Call[CmatCwasCdis(G ) Cm-pri ] NTallCm (9)

At the point when number N of all items is computed by utilizing the request passage Nord and the non-imperfect unit rate G, for example, condition, [6] the working time TV for the machine apparatus V is figured by every machine instrument, the quantity of all items N, machining condition, the course of action time and the advance of the work. The working time Tm for the item is ascertained by the condition, [7] add up to working time Tall is computed by the working time Tm and number N of all items, for example, condition, [8] and unit cost of material is Cmat, unit cost of utilization article is Cwas, squander cost for mediocre merchandise is Cdis, amortize cost of the utilized machine instruments for the item is Cm-pri and work cost for one hour is Cm, Total creation cost is figured by the condition. [9]

Evaluation using spring back on press of magnesium alloy

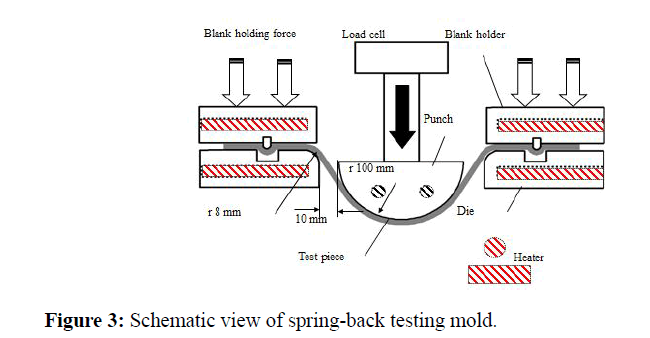

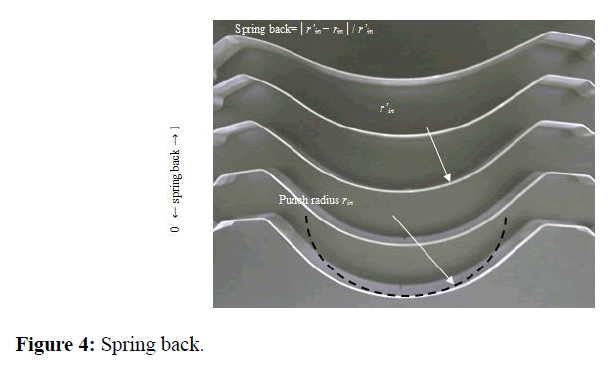

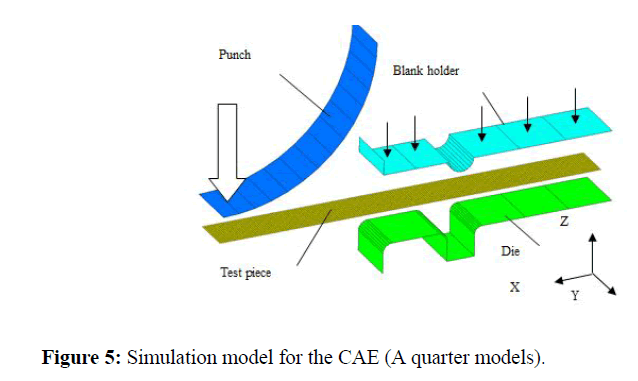

CAE and an analysis utilizing the press of magnesium compound were performed for assessment of this framework. Test set-up of press with AZ31 magnesium composite was appeared in Figure 3. [2] This assessment was utilized a spring back, for example, Figure 4. This esteem turned into the sought esteem in our framework. Reproduction display for the CAE was appeared in Figure 5. This is a quarter model of the trial set-up. The control considers and the commotion calculates in Table 1 were information of the CAE. Information of the administration for profitability was appeared in Table 3. This is imperative information for choosing the ideal state of the outline. Control and commotion variables are appeared in Table 3. These variables are utilized as a part of the later test and are critical figures the Taguchi techniques. Every element has a few levels. Control components are equivalent to the outline variables. Clamour variables are happened for the mistake of capacity on the item. Here, when the dissemination information or many qualities for commotion components were utilized, SN proportions and affectability of the sought property or midpoints and standard deviations for all blends of the control elements were figured with high precision. At that point computation precision of this framework turned out to be great. All blends utilizing all control elements are 4374(=6 × 36) sorts for Table 1, however these mixes were compacted to 18 sorts of orthogonal exhibit. Impact of the nose elements was researched with respect to 25 times (=2: greatest and least vales of every commotion calculate, 5: number of clamour variable) for every blend of the control components. Along these lines number of the CAE counts for this situation was 576 times (=18 kinds × 25 times). The request condition and the cost table are appeared in Table 4. This is the information for the later assessment on the press. At that point the ideal mix of the control consider for the need thing was chosen. The need things are achievement rate, precision, producing time or aggregate cost. Around then, the originator can choose the need in the efficiency figures on the outline organize.

| Control factors | Levels | 1 | 2 | 3 | 4 | 5 | 6 | |

| Tension (MPa) | 10 | 50 | 90 | 130 | 170 | 210 | ||

| Levels | 1 | 2 | 3 | |||||

| Punch speed (mm/min) | 150 | 300 | 500 | |||||

| Temperature of die | 100 | 200 | 250 | |||||

| Lubricant | Teflon | Lub.C | Lab.D | |||||

| Test piece | Mat.M | Mat.O | Mat.Ob | |||||

| Die radious (mm) | 6 | 8 | 10 | |||||

| Clearance (mm) | 5 | 10 | 15 | |||||

| Noise factors | Levels | 1 | 2 | |||||

| Blank holding force (%) | -10 | 10 | ||||||

| Blank holding force (%) | -5 | 5 | ||||||

| k value (Work hardening coefficient) | Mat. M (%) | -1.5 | 1.5 | |||||

| Mat. O (%) | -3.0 | 3 | ||||||

| Mat. Ob (%) | -10 | 10 | ||||||

Table 3: Control and noise factors.

| Order condition | Tolerance | 0.01 | |

| Order entry(uint) | 1000 | ||

| Delivery (hour) | 24 | ||

| Cost | Magnesium sheet | Mat.M(yen/unit) | 260 |

| Mat.O(yen/unit) | 180 | ||

| Mat.Ob(yen/unit) | 180 | ||

| Lubricant | Teflon(yen/unit) | 50 | |

| Lub.D(yen/unit) | 0.053 | ||

| Lub.C(yen/unit) | 0.304 | ||

| Disposal cost (yen/unit) | 2.16 | ||

| Charge rate (yen/hour) | 2000 | ||

Table 4: Order condition and cost table.

Consequences of assessment for this framework are appeared in Table 5. These outcomes are the every need for precision; add up to cost, fabricating time or non-imperfect unit rate. The ideal mix utilizing the control components and its levels for every need are additionally appeared in Table 5. These were every best mix for the need thing.

| Priority item | Spring back ηave | Total cost Call | Total time Tall | Non defective unit rate G | |

|---|---|---|---|---|---|

| Press condition | Tension (MPa) | 170 | 170 | 170 | 170 |

| Punch speed (mm/min) | 300 | 300 | 500 | 300 | |

| Temperature of die (℃) | 200 | 200 | 200 | 200 | |

| Lubricant | Teflon | Lab.D | Teflon | Teflon | |

| Test piece | Mat.O | Mat.O | Mat.O | Mat.O | |

| Die radius (mm) | 10 | 10 | 10 | 10 | |

| Clearance (mm) | 5 | 5 | 15 | 15 | |

| Results | Spring back | 0.0039 | 0.0091 | 0.0071 | 0.0042 |

| Non defective unit (%) | 100 | 97 | 99 | 100 | |

| Number of processing (unit) | 1000 | 1029 | 1013 | 1000 | |

| Total time (hour) | 7.8 | 8 | 4.7 | 7.8 | |

| Total cost (10000 yen) | 24.6 | 20.2 | 24.2 | 24.6 | |

Table 5: Result of evaluation for this system.

The Analysis for Investigation Regarding the Influence of the Control Factor

Explanation for analysis for investigation regarding the influence of the control factors

Presently, imaginative advancement with short-term, ease, work sparing and vitality sparing is additionally required on the planet. Along these lines, in this examination, the product for creative device utilizing Taguchi-techniques is produced and assessed. [12-14] At in the first place, first trial examines unpleasant functions in regards to all levers of all control elements, and then vital control variables and aimless control elements were sorted with the few remarks for the second trial. Around then, greatest, middle of the road and least values for every lever of the every control element ought to utilize for quest for all potential outcomes. At that point second trial chooses the ideal mix utilizing the levels of the control considers by more detail trial utilizing just imperative control variables. The second trial is striven for getting the best mix utilizing the ideal level of every control figure.

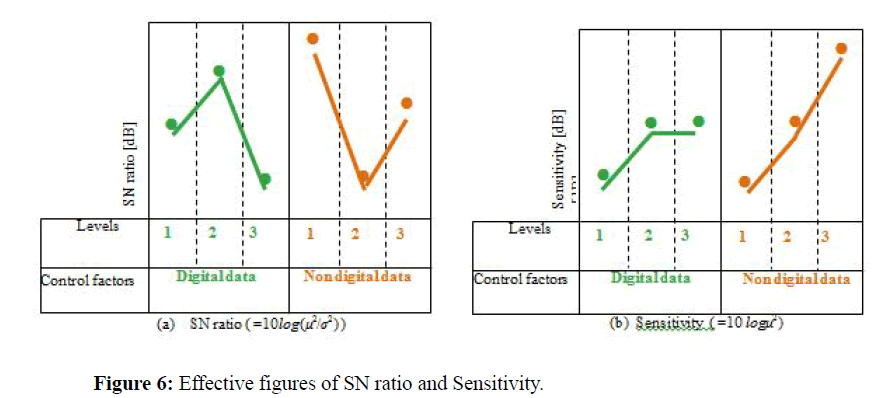

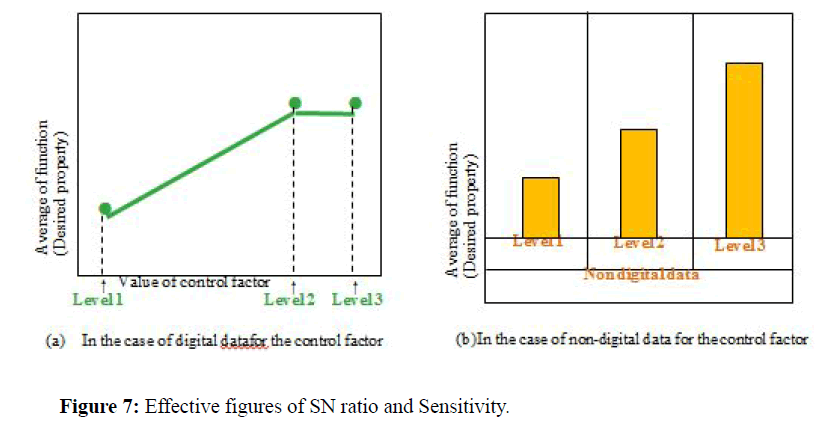

The control variables comprise of advanced information and non-computerized information. At the point when this information are inputted in the product of Taguchistrategies, the consequences of the successful figures for both SN proportion and Sensitivity can compute, for example, Figure 6. If there should be an occurrence of Taguchi-techniques, after a few assessments were performed by utilizing the powerful figures, the trial was finished. In this way our unique framework begins from here; then Figure 6 is revised to Figure 7. Around then, even pivot is the levels of the every control, and vertical hub is utilized the normal of capacity (wanted property) or it standard deviation. If there should arise an occurrence of the computerized information, a line diagram is utilized, for example, Figure 7(a), and if there should be an occurrence of the non-advanced information, a line chart is utilized, for example, Figure 7(b). Everybody can naturally and outwardly feel the impacts of the control considers by utilizing the Figure 7, can get a handle on for the physical picture with respect to the impacts of the control elements. If there should be an occurrence of the line chart, then the working of check fit is performed by utilizing exponential, straight, logarithmic, polynomial and radical approximations. In here, an administrator can intuitively comprehend the impacts of the control variables. If there should arise an occurrence of a structured presentation, Figure 7(b) couldn't change to Figure 8.

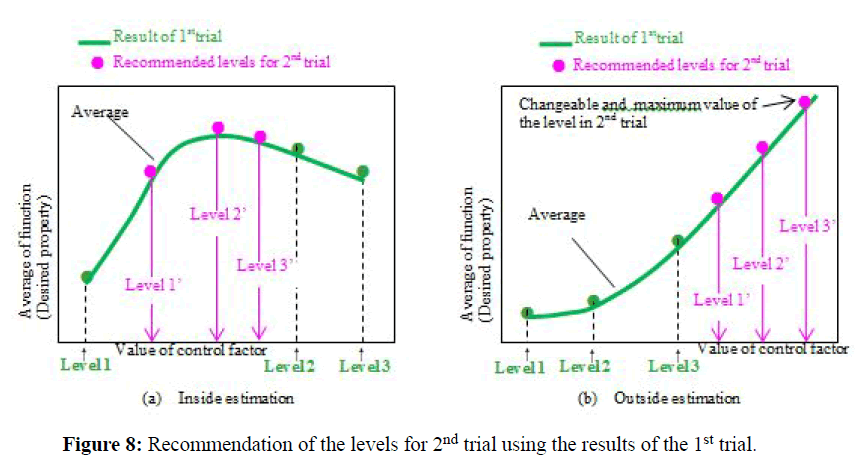

The ideal levels of the control components for the second trial were chosen by utilizing the consequences of the main trial. The strategy for determination of the ideal levels of the control elements is appeared in Figure 8. In the clarification, it assumes that the bigger capacity is craved by everybody. The bend of Figure 8(a) has a mountain shape, there is the optimum lever of the control consider the locale of first trial. In this manner new level 2' is chosen to the highest point of the mountain, new level 1' is center between the old level 1 and the new level 2', and new level 3' is center between the new level 2'and the old level 2. Level 1', level 2' and level 3' are the ideal levels for the second trial. The bend of Figure 8(b) has a state of chart ascending to one side, there is the optimum lever of the control calculate the correct locale of first trial. In this way new level 3' is chosen to the practicable huge esteem, new level 1' and new level 2' divide into three districts between the new level 3'and the old level 3. The administrator of the product can choose standard deviation for vertical hub, around then, the administrator can appraise strength for the commotion components.

Evaluation using heat transfer coefficient regarding the forced cooling

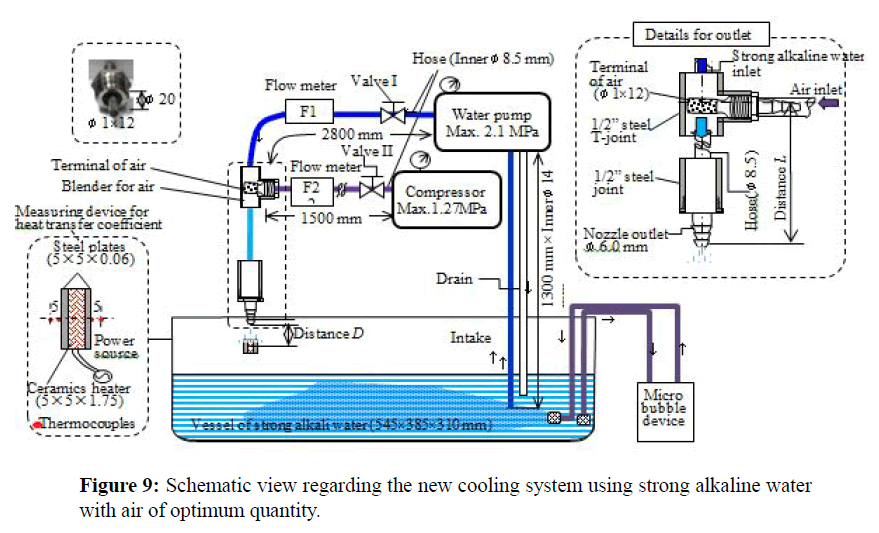

At last, wet cutting using strong alkaline water with air of optimum quantity was used for evaluation of the innovative tool. Experimental set-up is shown in Figure 9. Micro bubble is always supplied for high heat transfer coefficient in strong alkaline water. The strong alkaline water with micro bubble is dew from the vessel and is supplied to the blender for air. Air is also supplied to the blender for air by the compressor. Strong alkaline water and air are mixed in the blender for air and are supplied to the nozzle for outlet.

In the assembling field, everybody is coveted high warmth exchange coefficient. In this manner warm exchange coefficient is utilized for the capacity as a part of the proposed imaginative device. The control and clamour components for first trial are appeared in Table 6. At that point, the ideal amounts of solid soluble water and air were researched for high cooling productivity in the try different things with Table 6. Around then, the proposed imaginative device was utilized for plan of the second trial.

| Control factors | Noise factor | ||||||||

| Name of factors | Length L (mm) of hose between the blender for air and the nozzle for outlet | Air pressure | Quantity of flow for strong alkaline waterQ (L/min) | Distance D (mm) between the nozzle for outlet and the sensor |

Number of experiments: 9 | ||||

| P (MPa) | |||||||||

| 1st trial | 2nd trial | 1st trial | 2nd trial | 1st trial | 2nd trial | 1st trial | 2nd trial | ||

| Level 1 | 500 | 70 | 0.05 | 0.15 | 0.5 | 4 | 10 | 150 | |

| Level 2 | 1000 | 250 | 0.2 | 0.2 | 3 | 5 | 200 | 200 | |

| Level 3 | 5000 | 500 | 0.4 | 0.25 | 6 | 6 | 400 | 250 | |

Table 6: Control and noise factors for 1st and 2nd trials regarding the cooling system for evaluation of the software. The cell with light blue is an optimum condition which was decided after 2nd trial.

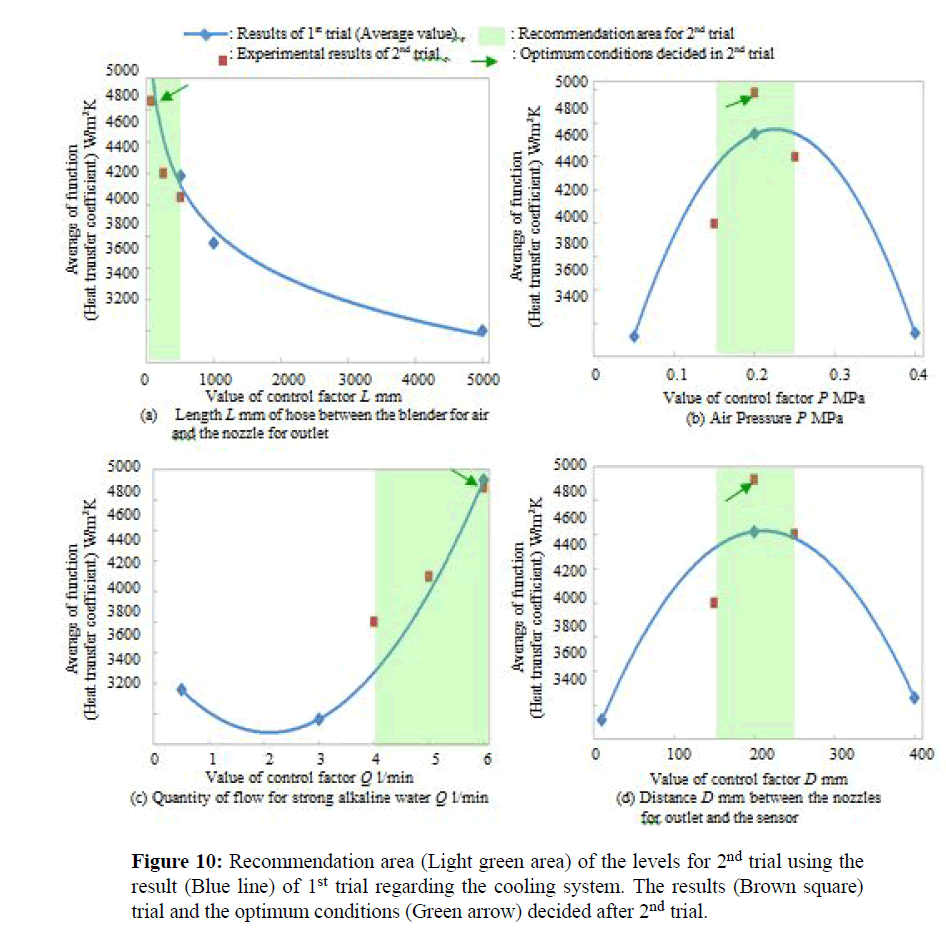

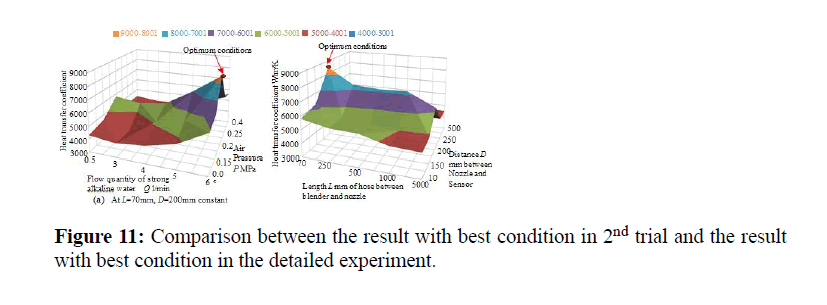

Results of the first trial are shown in Figure 10. There are the results of the first trial (Blue line) and the results of the recommendation area (Light green area) of the levels for 2nd trial in Figure 10. Shapes of graphs in (b) and (d) are mountain shape. Therefore middle region were selected for the second trial regarding (b) and (d). As (a) and (c) were graphs rising to the left and right, therefore the more left region and the more right region were selected for the second trial regarding (a) and (c), respectively. The control factors and the noise factors for the second trial are also shown in Table 6. After the experiment with Table 6, the experimental results of the second trial were calculated by the proposed innovative tool (Brown square). The results of the second trial are also shown in Figure 11. Averages of heat transfer coefficient for the second trial were larger than those for the first trial. The proposed innovative tool could estimate the good region for the second trial. The optimum levels of the each control factor are decided by using Figure 11 (Green arrow). The optimum condition are also shown in Table 6; Optimum length L mm of hose between the blender for air and the nozzle for outlet is 70 mm, optimum air pressure P is 0.2 MPa, optimum quantity of flow for strong alkaline water Q is 6.0 l/min and optimum distance D mm between the nozzle for outlet and the sensor is 200 mm. And heat transfer coefficient of the proposed cooling system with optimum condition was improved to 8490 W/m2K.

Hear exchange coefficient with a few conditions with length L mm of hose between the blender for air and the spout for outlet, gaseous tension P MPa, amount of stream for solid antacid water Q l/min and separation D mm between the spout for outlet and the sensor were measured and were appeared for examination in Figure 7. Warm exchange coefficient 8490 W/m2K which was sought by the proposed creative instrument was the biggest esteem in the all trials. In this way the proposed inventive device is powerful for imaginative improvement in the mechanical world.

Conclusion

It is concluded from the result that;

(1) The fabricate emotionally supportive network utilizing Taguchi techniques was produced.

(2) The proposed technique anticipated ideal handling conditions viably in every need.

(3) The anticipated outcomes fit in with the aftereffects of the genuine spring back test.

(4) Innovative device utilizing the Taguchi strategies was valuable for advancement with transient and lower cost.

(5) This device could rapidly and precisely choose the ideal cooling condition. The cooling framework with ideal condition utilizing the inventive device was exceptionally powerful. What's more, heat transfer coefficient of the proposed cooling framework with ideal condition was 8490 W/m2K.

References

- Tatebayashi K. Computer aided engineering combined with taguchi-methods, Proceeding of the Annual Meeting of the Japan Society of Mechanical Engineering 2005; 8: 224-225.

- Sugai H. Prediction of Optimum Machining Condition in Press Forming Using Taguchi-methods and FEM Simulation. Transactions of the JSME 2006; 72: 3044-3051.

- Makino T. Optimization of Exhaust Port using Computer Simulation. Proceedings of the 13th Quality Engineering Society Conference 2006; 6-9.

- Fujikawa S. Optimum Parameter Design using the Taguchi methods for Finite-Element Analysis of 3D Forging Deformation, Journal of the Japan Society of Technology for Plasticity 1999; 40: 1061-1065.

- Tanabe I. Development of Manufacture Support System Using Taguchi methods; APMS 2009. IFIP 2010; 8: 522-529.

- Tanabe I. Development of Manufacture System Taguchi methods; APMS 2010. IFIP 2011; 9: 522-529.

- Tanabe I. Innovation Tool Using Taguchi-Methods for Development of a New Product with Optimum Condition. ADMOS 2013; 10: 642-651.

- Tatebayashi K. Computer Aided Engineering with Taguchi methods. Proceeding of the 2005 Annual Meeting of the Japan Society of Mechanical Engineering. 2005; 8: 228-229.

- Tanabe I. Development of Simulation System on CAE without Trial Working for Products(Manufacture of High Precision System Using Dispersion of Error Factors). Transactions of the JSME (in Japanese).2009; 75: 203-209

- Tanabe I. Evaluation of Influence Regarding Control Factors Using Inverse Analysis of Taguchi Methods (Influence Regarding Organic Matter in Control Factors). Transactions of the JSME (in Japanese) 2011; 77: 3117-3126

- Nagakura S. Iwanami Physics and Chemistry Dictionary (in Japanese). Iwanami Shoten 1988; 1234.

- Tanabe I. Development of Innovative Tool Using Taguchi-methods. AASRI Procedia 2014; 9: 107-113.

- Sakamoto H., Tanabe I., Takahashi S. Development of Software for Calculation OD Best Condition Using Taguchi Methods and Its Evaluation. Journal of Machine Engineering 2015; 15: 44-54.

- Sakamoto H., Tanabe I., Takahashi S. Development for Sound Quality Optimisation by Taguchi Methods. Journal of Machine Engineering 2015; 15: 69-81.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences